Abrupt Change in Bearing Piles Blow Count The soil could have greater strength, higher damping ration, or larger soil quakes than initial testing anticipated.

Driving system problems can be related to low hammer efficiency or cushion that is too soft. (Something that should be done before the work is started.) If they are matched, make sure the driving system operation conforms to the equipment manufacturer’s guidelines. If it is taking a lot more blows to drive the pile than planned, there is an issue with the soil and / or the driving system.įirst ensure that the driving system is matched to the pile type. It is based on the soil and the driving system. The number of blows needed to drive the pile to the required depth is calculated in advance. Here are common issues and solutions related to blow count: Increased Blows Needed to Drive Pile If the blow count is different in the field, there’s likely a problem. Drive Pile Blow Count Issuesīlow counts are calculated in advance. Solutions can be included in contingency planning – avoiding cost overruns. The project’s risk mitigation plan can consider likely issues to be encountered. The challenging aspect of dealing with soil presents a variety of problems that can be anticipated. Testing and evaluation should continue during construction. The planning process must include extensive and careful soil testing. Determining the right design is difficult. As well, soil – particularly in a large area – can vary greatly. Keep in mind that driving the piles alters how the soil around it will behave. Other factors include the material of the piles, the expected load, and the level of use anticipated. The design of a pile foundation is highly dependent on the soil the piles are driven into. For the single acting hydraulic hammer, the free-falling piston develops the actual energy induced into the pile–much the same power stroke as a drop hammer or a single acting air/steam hammer. Hydraulic Impact HammerĪ hydraulic hammer incorporates the use of an external energy source to lift the hammer to the top of its stroke. This type of hammer greatly increased the speed with which piles could be driven. Active pressure accelerates the ram during the down stroke. These hammers increase the blow rate with a shorter stroke. It will keep going until it runs out of fuel or is manually stopped. When it hits the pile, the energy drives it back up. The ram is raised then released and allowed to free-fall. This drop hammer uses a two-stroke diesel engine. They drive piles faster and their operation is (comparatively) quieter. Vibratory hammers cut soil rather than drive piles using a spinning technique and counter-weight system. There are several types of pile drivers, including: Vibratory Hammer It is placed between the helmet and the pile. Pile CushionĪ pile cushion is typically made of wood. The helmet is a temporary steel cap placed on top of the pile used to, as much as possible, protect the head during driving. Hammer CushionĪ hammer cushion, typically made of man-made materials, is placed between the striker plate and helmet. Leads keep the piling and hammer aligned.

PILE CAP FOUNDATION SOFTWARE DRIVER

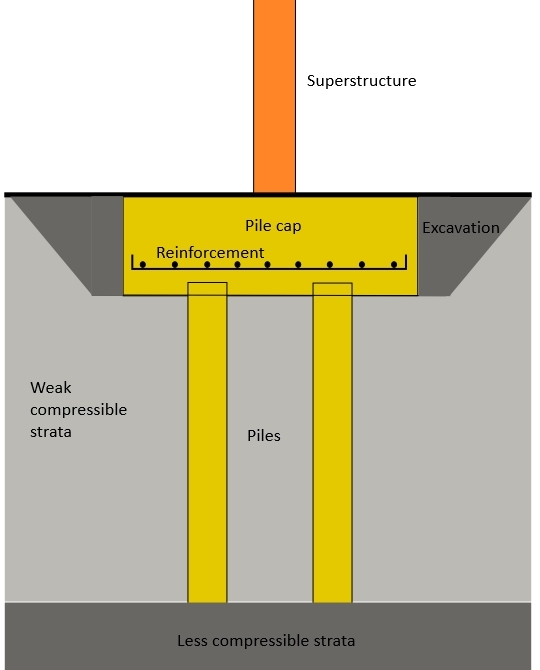

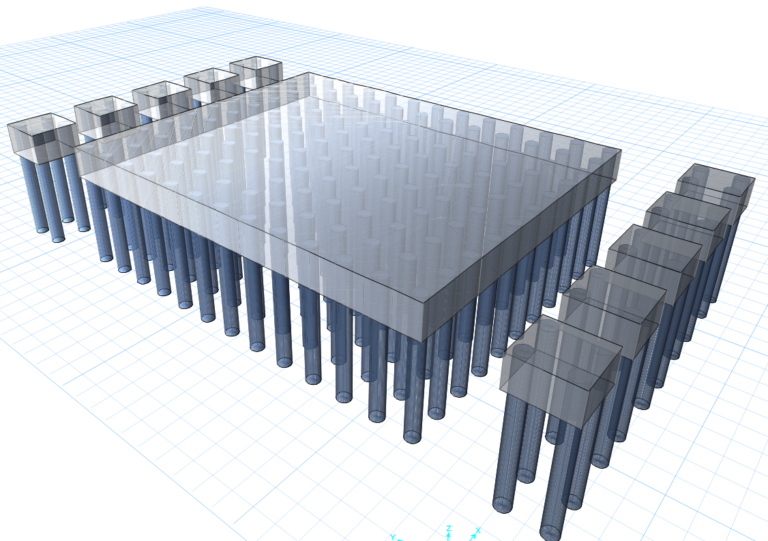

They are categorized by how they attach to the pile driver – hanging, fixed, or swinging. The pile driver lead is a supporting framework that guides the pile and hammer. Each part has a role in transferring energy to the pile which in turn impacts hammer performance. Photo credit: Junttan Anatomy of a Pile DriverĪt a high level, a pile driving system has four main parts: lead, hammer cushion, helmet, and pile cushion. To support heavy loads, they are grouped under footings.

PILE CAP FOUNDATION SOFTWARE SKIN

Most of the load capacity is generated from skin friction. Many of today’s pile driving hammers are powered by diesel or hydraulic systems. In the twentieth century, greater driving force was achieved by using air- or steam-powered machines to accelerate the ram’s downward action.

The energy required to drive a pile was created by the weight of the ram falling through the gravity field. Early Pile DrivingĮarly pile driving was done by hand. In this article we discuss pile driving basics, the common problems encountered, and potential solutions. The piles are a type of deep foundation used to hold up large structures – often bridges. Vertical columns made of various materials (wood, concrete, steel, or a combination) are driven into un-excavated soil. Pile driving is a critical part of the construction process.

0 kommentar(er)

0 kommentar(er)